Reliability. Efficiency. Reputation.

Contract manufacturing of furniture for the needs of your business is one of our key activity areas. "KompaniT" has extensive experience in designing and manufacturing new, and most importantly, large batches of products. The convenient location of the company in the central part of Eastern Europe, clear and transparent terms of business, European quality and minimum production costs give tangible advantages of cooperation with the furniture factory "KompaniT".

Our capabilities:

Expansion of operations

We are interested in the development of our partners and are always ready to scale the volumes, due to our production capacity.

Product range

There are more than 400 types of own products in the warehouses. There is the possibility of production of our types under your trademarks. We can also develop and launch the serial production of your products.

Individual packaging, branding, instructions

Adapting of the product to the needs of your market

Benefits of White Label

Price

The production volume of more than 500 thousand products per year, direct supplies of materials and components, optimization of the production process make it possible to set the most competitive price on the market.

Quality

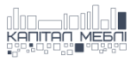

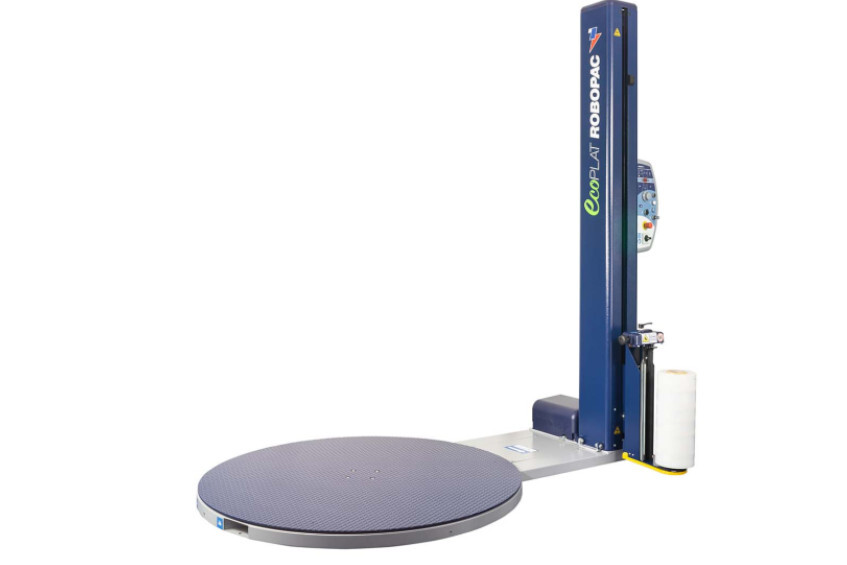

A separate production line for working under the White Label program, which is equipped with the most modern equipment, allows us to be confident in the high quality of our products.

Efficiency

We offer the best indicators in terms of production time among all the Ukrainian manufacturing companies. The factory is ready to ship more than 10 thousand products per week under the White Label program.

Examples of White Label products

When your task is to establish the supply of a certain type of product, our company will provide the optimal result with strict compliance with deadlines and international quality standards for furniture products

How do we work?

more

10 000

satisfied customers

more

20

years on the market

more

350 000

products manufactured per year

more

50 000

PRODUCTS AVAILABLE IN STOCK

Equipment

Order form

Send us an application and our manager will contact you shortly